Welder

Tupelo, MississippiOverview

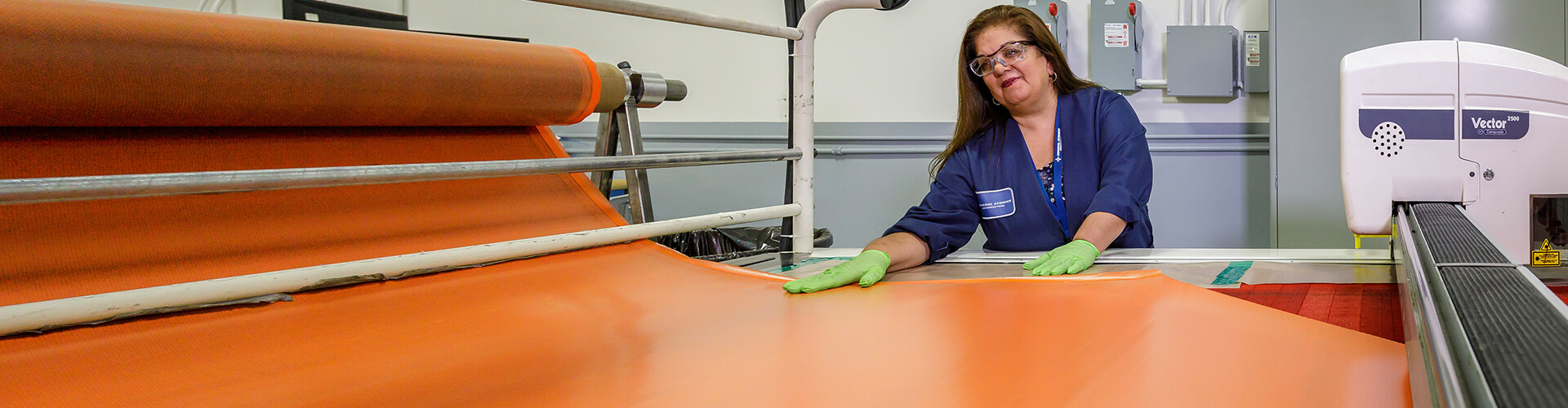

Assemblers, Machinists, Material and Production Control, Composite Technicians, Coordinators, Planners and Stock Clerks. These are just a few of the Manufacturing positions we offer at General Atomics. As a Manufacturing team member, you will use high-tech machines, systems, equipment and tools to create and build our products.

Experience in handling composite materials, using CNC machines and software, reading blueprints and drawings and a general understanding of manufacturing prinicples and systems are all desirable qualifications.

Schedule: Full-Time Hourly

Job Level: Mid-Level (3-7 years)

Travel: 0 - 25

Success Profile

What makes a successful Welder at General Atomics? Check out the top traits we’re looking for and see if you have the right mix.

- Detail Oriented

- Team Player

- Results Driven

- Organized

- Productive

- Problem Solver

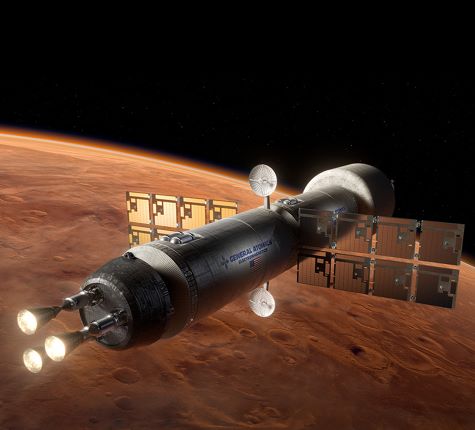

Job Summary General Atomics Electromagnetic Systems (GA-EMS) designs and manufactures first-of-a-kind electromagnetic and electric power generation systems. GA-EMS’ expanding portfolio of specialized products and integrated system solutions support critical fleet, space systems and satellites, missile defense, power and energy, and process and monitoring applications for defense, industrial, and commercial customers worldwide.

Under limited supervision, this position is responsible for performing critical, complex welding processes on aluminum and steel parts and assemblies to required tolerances using welding metals and metal alloys. Sets up and operates welding equipment to produce high quality welds in both standard and non-standard shapes and sizes. Follows complex verbal and written instructions including blueprints, sketches and production documentation; participates in the development and review of operating procedures, safety guidelines, and manufacturing practices; maintains required certifications/qualifications, and may function in a leadership role to less experienced professional staff.

DUTIES AND RESPONSIBILITIES:

- Follow all safety procedures, work instructions, weld procedures, workmanship procedures and any and all procedures related to performance of assigned work.

- Interact with customers and auditors in a professional manner.

- Expected to work in a safe manner in accordance with established operating procedures and practices.

- Sets up and operates all welding equipment used in work operations to produce high quality welds in both ferrous and non-ferrous materials.

- Sets up and operates other welding equipment in the weld shop such as cutting, brazing, and local heat treatment equipment.

- Determines layouts, plans and fabricates components working from blueprints, sketches, production travelers, and/or verbal instruction.

- Makes difficult welds where the configuration and techniques require considerable ingenuity to minimize weld distortion and maintain acceptable dimensions.

- Works with inspectors to locate defects in welds using X-ray, dye penetrate, and other nondestructive inspections; remove defects and repairs weld.

- Arranges for proper tools and materials for work to be performed; monitors proper use of welding equipment and safety practices of group.

- Recommends required spare parts and welding supply inventories to supervisor.

- Maintains required certifications.

- Aids in the training of less experienced welders.

- May be the prime contact with supplier and vendors

- Performs housekeeping and cleanup duties as required.

- Responsible for observing all laws, regulations, and other applicable obligations wherever and whenever business is conducted on behalf of the Company.

- Other duties as assigned or required.

We recognize and appreciate the value and contributions of individuals with diverse backgrounds and experiences and welcome all qualified individuals to apply.

Job Qualifications:

- Typically requires a High school diploma or equivalent and five years or more related welding experience.

- Must have the required certifications and demonstrate a detailed understanding of welding concepts, and practices including complex manufacturing documentation such as diagrams, drawings, specifications and work instructions and knowledge of GTAW, GMAW, SMAW and other comparative welding techniques.

- Must possess:

- the ability to communicate and understand written and verbal communication;

- the ability to identify, analyze, interpret and report on issues, contributing solutions to non-routine problems;

- the ability to use independent judgment in performing welding functions; and, (4) excellent interpersonal communication skills to explain detailed information and effectively communicate with all levels of employees, external customers and management.

- Must be able to meet requirements for operation of forklifts and overhead cranes.

- Ability to work both independently and in a team environment as a leader is essential as is the ability to work extended hours or on alternate shifts as required.

- Welders must be able pass performance qualifications to the following welding codes for both plate and pipe welding on various Carbon and quenched and tempered steels, Nickle Alloys, Nickle-Chrome Alloys, Copper alloys, Aluminum, Titanium, and dissimilar materials. Must qualify on site, qualifications can’t transfer from previous jobs:

- ASME Section IX

- NAVSEA S9074-AQ-GIB-010/248

- AWS D1.1

- AWS D1.2

- AWS D1.6

- AWS D9.1

- AWS D17.1

- Welding experience with below is desired:

- NAVSEA T9074-AD-GIB-010/1688 Workmanship

- NAVSEA S9074-AR-GIB-010/278 Workmanship

- ASME Section IX

- Welding High Strength Steel Alloys

Salary:$59,410 - $90,730

Benefits

-

Competitive Pay

-

Paid Time Off

-

Healthcare

-

Multiple product lines means a variety of work

-

Pension, 401(k)/Retirement Plans

-

Travel

“The people I work with and the great opportunities to grow are the reasons I look forward to coming to work every day.”– Ralph, Technician

“I enjoy working with good people and knowing I am helping our great military.”– Joe, Fabricator

“I chose General Atomics because I wanted to work in a challenging work environment.”– Tony, Composite Technician

“I'm excited to come to work because of the new projects and challenges.”– James, Quality Composite Inspector

News

-

Featured Jobs

- Legal Assistant San Diego, California

- Electrical Engineer, Hardware and Circuit Board Design Lead San Diego, California

- Electrical Engineer, Hardware Description Language (MODEM), and Embedded Software San Diego, California

- Electrical Engineer, MODEM Architect San Diego, California

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Legal Assistant San Diego, California

- Electrical Engineer, Hardware and Circuit Board Design Lead San Diego, California

- Electrical Engineer, Hardware Description Language (MODEM), and Embedded Software San Diego, California

- Electrical Engineer, MODEM Architect San Diego, California

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Legal Assistant San Diego, California

- Electrical Engineer, Hardware and Circuit Board Design Lead San Diego, California

- Electrical Engineer, Hardware Description Language (MODEM), and Embedded Software San Diego, California

- Electrical Engineer, MODEM Architect San Diego, California

You have not recently viewed any jobs.

You have no saved jobs.