Senior Level Machinist

Tupelo, Mississippi

Overview

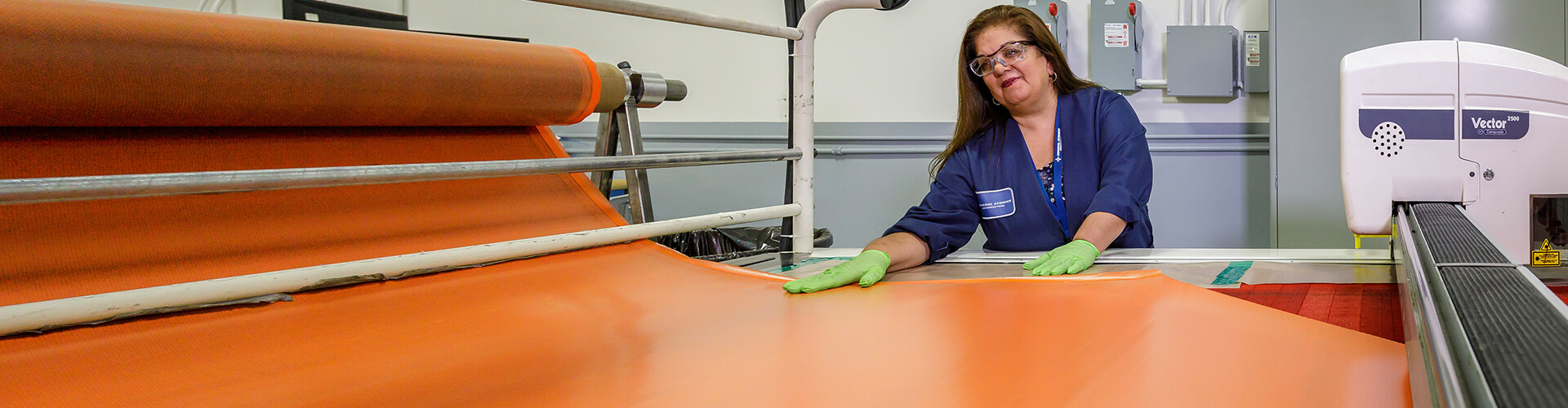

Assemblers, Machinists, Material and Production Control, Composite Technicians, Coordinators, Planners and Stock Clerks. These are just a few of the Manufacturing positions we offer at General Atomics. As a Manufacturing team member, you will use high-tech machines, systems, equipment and tools to create and build our products.

Experience in handling composite materials, using CNC machines and software, reading blueprints and drawings and a general understanding of manufacturing prinicples and systems are all desirable qualifications.

Schedule: Full-Time Hourly

Job Level: Senior (8+ years)

Travel: 0 - 25

Success Profile

What makes a successful Senior Level Machinist at General Atomics? Check out the top traits we’re looking for and see if you have the right mix.

- Detail Oriented

- Team Player

- Results Driven

- Organized

- Productive

- Problem Solver

Job Summary General Atomics Electromagnetic Systems (GA-EMS) designs and manufactures first-of-a-kind electromagnetic and electric power generation systems. GA-EMS’ expanding portfolio of specialized products and integrated system solutions support critical fleet, space systems and satellites, missile defense, power and energy, and process and monitoring applications for defense, industrial, and commercial customers worldwide.

Under limited supervision, this position is responsible for performing complex functions related to machine tools. Sets up and operates one or more of the following: Mills (vertical or horizontal), Mill Turns, 4th and 5th axis mills various types of lathes, and grinders to machine or grind developmental, production or maintenance parts to exacting tolerances and dimensions. Expected to provide guidance or training to equal or lower level machinists.

ROLES AND RESPONSIBILITIES:

- Plans sequence of machine operation as required using drawings, sketches or other written or verbal instructions.

- Reviews engineering drawings, sketches, graphic illustrations or verbal/written correspondence to compute angular and linear dimensions. Able to determine cutting tools to be used, method of holding, and machine speeds and feeds.

- May monitor and verify quality of work performed by equal or lower level personnel, such as first part inspection.

- Sets up tooling and production stock to be machined using a wide variety of both conventional and CNC machining equipment to perform machining of complex parts by drilling, reaming, boring, tapping, thread milling, slotting, dovetailing, etc. on ferrous and non-ferrous metals and other materials.

- Designs, fabricates, and/or improvises tooling, and tooling aids to assist in machine setups utilizing various shop equipment.

- Performs preventive maintenance and makes machine adjustments as required using hand tools and precision measuring instruments.

- May provide guidance or training to equal or lower level machinist.

- Responsible for observing all laws, regulations, and other applicable obligations wherever and whenever business is conducted on behalf of the Company.

- Expected to work in a safe manner in accordance with established operating procedures and practices.

- Other duties as assigned or required.

Job Qualifications:

- Typically requires an associate's degree, technical/trade school training or equivalent and seven or more years related experience. Additional experience may be substituted for formal education.

- Must be customer focused and possess:

- the ability to perform complex set-up and fabrication of machined parts with little or no direction

- in-depth knowledge of machining equipment including ability to use judgment and safe practices

- ability to read, interpret and explain engineering drawings, sketches and verbal and written instructions

- skills to maintain the flow of work within the unit using independent judgment in solving moderately complex problems and recommending solutions

- strong interpersonal skills and written communication skills to interface with employees and management

- basic computer skills

- The ability to work both independently and lead in a team environment is essential as is the ability to work extended hours as required.

Salary:$59,410 - $90,730

Benefits

-

Competitive Pay

-

Paid Time Off

-

Healthcare

-

Multiple product lines means a variety of work

-

Pension, 401(k)/Retirement Plans

-

Travel

“The people I work with and the great opportunities to grow are the reasons I look forward to coming to work every day.”– Ralph, Technician

“I enjoy working with good people and knowing I am helping our great military.”– Joe, Fabricator

“I chose General Atomics because I wanted to work in a challenging work environment.”– Tony, Composite Technician

“I'm excited to come to work because of the new projects and challenges.”– James, Quality Composite Inspector

News

-

Featured Jobs

- Quality Inspector Electrical Tupelo, Mississippi

- Principal Avionics Systems Engineer CCA Programs Poway, California

- Flight Test Engineer Palmdale, California

- Senior SuccessFactors HRIS Analyst Poway, California

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Quality Inspector Electrical Tupelo, Mississippi

- Principal Avionics Systems Engineer CCA Programs Poway, California

- Flight Test Engineer Palmdale, California

- Senior SuccessFactors HRIS Analyst Poway, California

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Quality Inspector Electrical Tupelo, Mississippi

- Principal Avionics Systems Engineer CCA Programs Poway, California

- Flight Test Engineer Palmdale, California

- Senior SuccessFactors HRIS Analyst Poway, California

You have not recently viewed any jobs.

You have no saved jobs.