Production and Engineering Liaison

San Diego, CaliforniaOverview

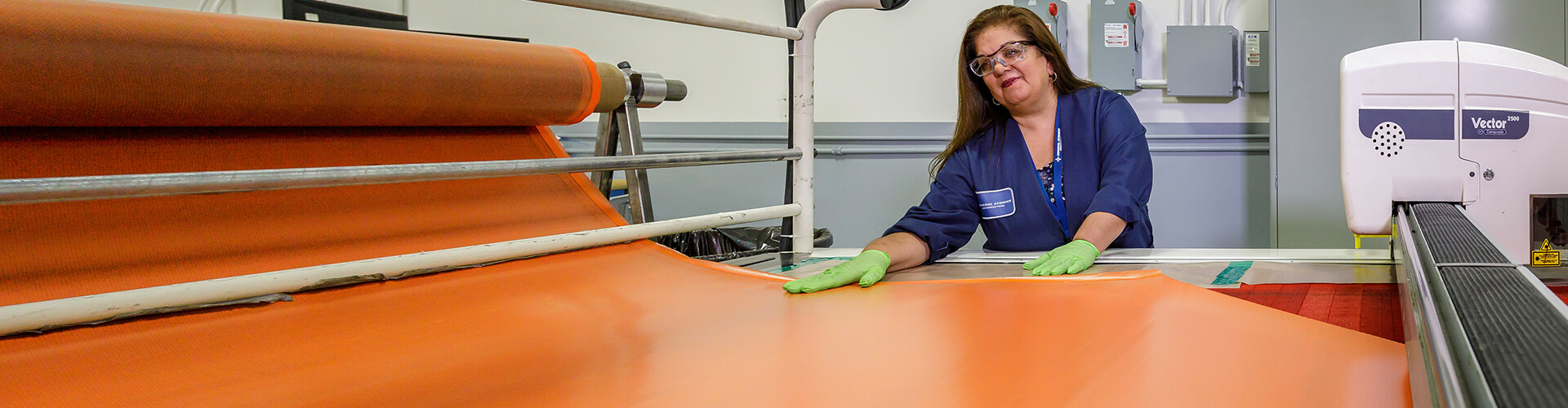

Assemblers, Machinists, Material and Production Control, Composite Technicians, Coordinators, Planners and Stock Clerks. These are just a few of the Manufacturing positions we offer at General Atomics. As a Manufacturing team member, you will use high-tech machines, systems, equipment and tools to create and build our products.

Experience in handling composite materials, using CNC machines and software, reading blueprints and drawings and a general understanding of manufacturing prinicples and systems are all desirable qualifications.

Schedule: Full-Time Salary

Job Level: Mid-Level (3-7 years)

Travel: 0 - 25

Success Profile

What makes a successful Production and Engineering Liaison at General Atomics? Check out the top traits we’re looking for and see if you have the right mix.

- Detail Oriented

- Team Player

- Results Driven

- Organized

- Productive

- Problem Solver

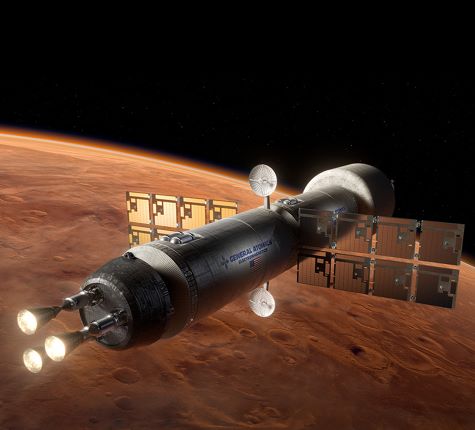

Job Summary General Atomics (GA), and its affiliated companies, is one of the world’s leading resources for high-technology systems development ranging from the nuclear fuel cycle to remotely piloted aircraft, airborne sensors, and advanced electric, electronic, wireless and laser technologies.

General Atomics Electromagnetic Systems (GA-EMS) designs and manufactures first-of-a-kind electromagnetic and electric power generation systems. GA-EMS' expanding portfolio of specialized products and integrated system solutions support critical fleet, space systems and satellites, missile defense, power and energy, and process and monitoring applications for defense, industrial, and commercial customers worldwide.

We currently have an exciting opportunity for a Production/Engineering Liaison to support the Nuclear Technologies and Materials (NTM) division within GA-EMS. Under limited supervision and review, this position will contribute to developing and controlling nuclear manufacturing processes and evaluating and resolving production issues related to nuclear fuel manufacturing, design, quality and material engineering.

DUTIES AND RESPONSIBILITIES:

- Analyzes, evaluates and resolves engineering related production problems.

- Analyzes, develops and controls manufacturing processes, procedures and tooling.

- Analyzes defective, damaged or malfunctioning parts, assemblies, equipment and systems; analyzes and routes non-conforming reports; develops and implements corrective action.

- Assists in development and execution of test plans to support nuclear fuel development with clearly defined logic, metrics, and timelines.

- Document findings and communicate reports at engineering meetings.

- Support future NTM engineering needs and the modifications required to accomplish technical goals.

- Address technical issues utilizing standard engineering and scientific principles to ensure accuracy, completeness, and timeliness of work.

- May represent group as member of change control board.

- Maintain the strict confidentiality of sensitive information.

- Work in a safe manner in accordance with established operating procedures and practices.

- Analyzes, investigates and documents design and process changes; coordinates with engineering and manufacturing departments.

We recognize and appreciate the value and contributions of individuals with diverse backgrounds and experiences and welcome all qualified individuals to apply.

Job Qualifications:

- Typically requires a Bachelor's degree and five or more years of progressive professional experience in a technical capacity in production operations. May substitute equivalent experience in lieu of education

- Must possess general knowledge of nuclear fuels, components, and systems, and have technical competency in lab environments.

- Understanding and experience in mechanical testing and other material characterization techniques (both destructive and non-destructive) is desirable.

- Must possess the ability to assist in design and execution of test plans.

- Experience in the space of nuclear manufacturing development is desirable.

- Must possess the ability to organize, schedule, and coordinate work phases.

- Ability to work independently and as part of a team; and ability to support development of technical projects.

Salary:$73,700 - $128,780

Benefits

-

Competitive Pay

-

Paid Time Off

-

Healthcare

-

Multiple product lines means a variety of work

-

Pension, 401(k)/Retirement Plans

-

Travel

“The people I work with and the great opportunities to grow are the reasons I look forward to coming to work every day.”– Ralph, Technician

“I enjoy working with good people and knowing I am helping our great military.”– Joe, Fabricator

“I chose General Atomics because I wanted to work in a challenging work environment.”– Tony, Composite Technician

“I'm excited to come to work because of the new projects and challenges.”– James, Quality Composite Inspector

News

-

Featured Jobs

- Legal Assistant San Diego, California

- Electrical Engineer, MODEM Architect San Diego, California

- Project Systems Engineer Poway, California

- Quality Engineer Tupelo, Mississippi

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Legal Assistant San Diego, California

- Electrical Engineer, MODEM Architect San Diego, California

- Project Systems Engineer Poway, California

- Quality Engineer Tupelo, Mississippi

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Legal Assistant San Diego, California

- Electrical Engineer, MODEM Architect San Diego, California

- Project Systems Engineer Poway, California

- Quality Engineer Tupelo, Mississippi

You have not recently viewed any jobs.

You have no saved jobs.