Machinist Precision Parts Beryllium

San Diego, CaliforniaOverview

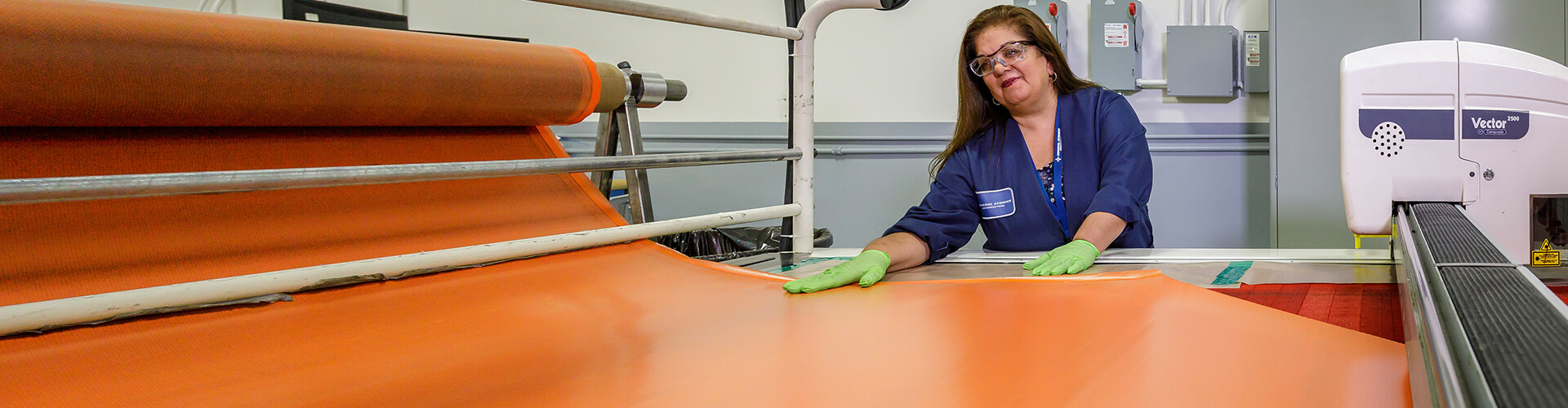

Assemblers, Machinists, Material and Production Control, Composite Technicians, Coordinators, Planners and Stock Clerks. These are just a few of the Manufacturing positions we offer at General Atomics. As a Manufacturing team member, you will use high-tech machines, systems, equipment and tools to create and build our products.

Experience in handling composite materials, using CNC machines and software, reading blueprints and drawings and a general understanding of manufacturing prinicples and systems are all desirable qualifications.

Schedule: Full-Time Hourly

Job Level: Mid-Level (3-7 years)

Travel: 0 - 25

Success Profile

What makes a successful Machinist Precision Parts Beryllium at General Atomics? Check out the top traits we’re looking for and see if you have the right mix.

- Detail Oriented

- Team Player

- Results Driven

- Organized

- Productive

- Problem Solver

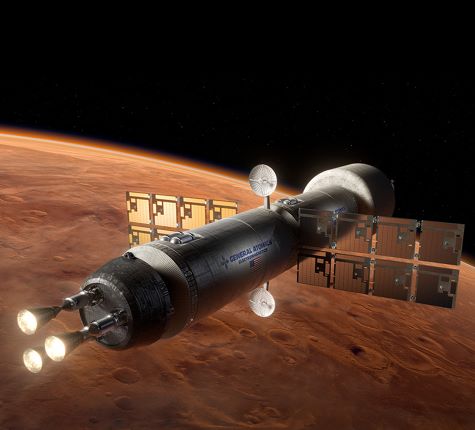

Job Summary General Atomics (GA), and its affiliated companies, is one of the world’s leading resources for high-technology systems development ranging from the nuclear fuel cycle to remotely piloted aircraft, airborne sensors, and advanced electric, electronic, wireless and laser technologies.

We have an exciting opportunity for a Machinist to join our Inertial Fusion Technology (IFT) division within the Energy group. The components to be machined are normally high-precision and in small quantities. Production schedules are reasonable but due dates are often inflexible. Salary potential commensurate with willingness/ability to grow professionally.

DUTIES AND RESPONSIBILITIES:

- Operates precision CNC lathes or mills along with standard machining equipment such as manual drill presses, lathes, mills, saws and shears..

- Being able to follow all safety procedures in working and machining in a laboratory that works with beryllium components.

- Set-up and operate CNC mills and lathes.

- NC programming in both manual (i.e., plain G-code and parametric G-code) and CAD/CAM (Creo/MasterCAM).

- Inspect parts using mics, calipers, digital height gages, measuring microscope, indicators, gage blocks, surface plates, sine plates, etc. as required.

- Inspect parts using high level inspection tools such as CT and white light optical profilers.

- Document inspection results by entering data into Excel templates and archiving on server.

- Work in a safe manner in accordance with established operating procedures and practices.

- Performs other duties as assigned or required.

We recognize and appreciate the value and contributions of individuals with diverse backgrounds and experiences and welcome all qualified individuals to apply.

Job Qualifications:

- Typically requires an associate's degree, technical/trade school training or equivalent and Six or more years related experience. Additional experience may be substituted for formal education.

- Must possess:

- Proficiency with common manual shop equipment such as lathes, mills, and saws.

- Some experience setting-up and operating NC mills and lathes.

- Some experience with NC programming (both G-code and CAD/CAM).

- Proficiency with common manual inspection tools such as micrometers, calipers, digital height gages, indicators, gage blocks, surface plates, and sine plates.

- Ability to read and understand engineering blue prints and diagrams.

- Skills to maintain the flow of work within the unit.

- Customer focus.

- Ability to use good judgment and safe practices in a shop environment.

- Time management skills to maintain the flow of work within the unit.

- Good interpersonal skills and written communication skills to interface with employees and supervisor; and basic computer skills.

- Ability to work in an large lab research environment requiring long periods of standing, walking, bending and lifting up to 50 lbs.

- Ability to work both independently and in a team environment.

- Flexibility to work extended hours as required.

- Pass requirements to wear a PAPR respirator.

- Ability to obtain and keep a DOE Q Level Security clearance

Salary:$56,180 - $83,518

Benefits

-

Competitive Pay

-

Paid Time Off

-

Healthcare

-

Multiple product lines means a variety of work

-

Pension, 401(k)/Retirement Plans

-

Travel

“The people I work with and the great opportunities to grow are the reasons I look forward to coming to work every day.”– Ralph, Technician

“I enjoy working with good people and knowing I am helping our great military.”– Joe, Fabricator

“I chose General Atomics because I wanted to work in a challenging work environment.”– Tony, Composite Technician

“I'm excited to come to work because of the new projects and challenges.”– James, Quality Composite Inspector

News

-

Featured Jobs

- Legal Assistant San Diego, California

- Electrical Engineer, Hardware and Circuit Board Design Lead San Diego, California

- Electrical Engineer, Hardware Description Language (MODEM), and Embedded Software San Diego, California

- Electrical Engineer, MODEM Architect San Diego, California

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Legal Assistant San Diego, California

- Electrical Engineer, Hardware and Circuit Board Design Lead San Diego, California

- Electrical Engineer, Hardware Description Language (MODEM), and Embedded Software San Diego, California

- Electrical Engineer, MODEM Architect San Diego, California

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Legal Assistant San Diego, California

- Electrical Engineer, Hardware and Circuit Board Design Lead San Diego, California

- Electrical Engineer, Hardware Description Language (MODEM), and Embedded Software San Diego, California

- Electrical Engineer, MODEM Architect San Diego, California

You have not recently viewed any jobs.

You have no saved jobs.