Production Planner

Poway, California

Overview

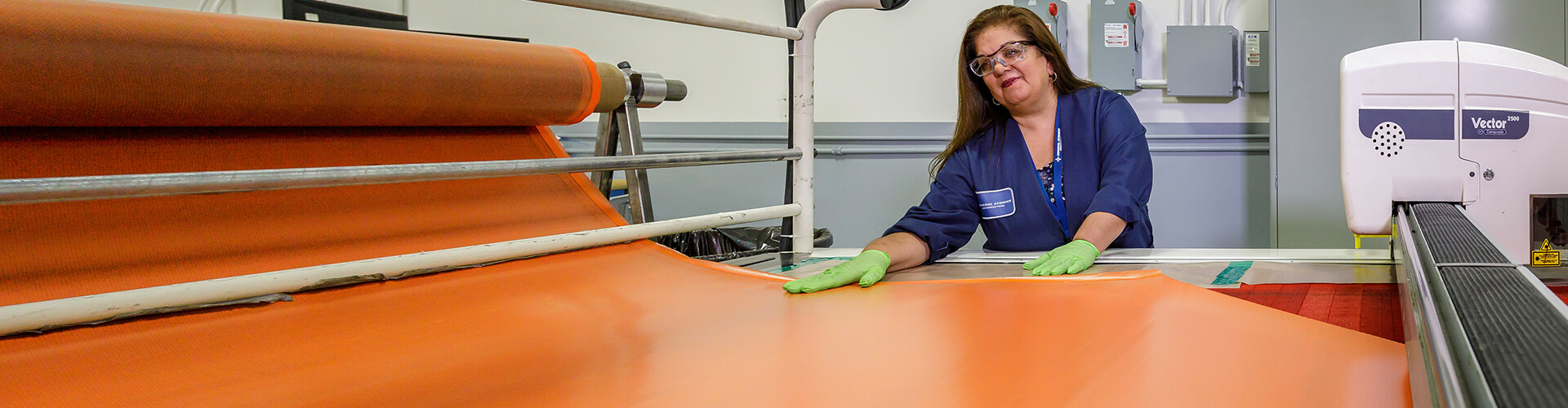

Assemblers, Machinists, Material and Production Control, Composite Technicians, Coordinators, Planners and Stock Clerks. These are just a few of the Manufacturing positions we offer at General Atomics. As a Manufacturing team member, you will use high-tech machines, systems, equipment and tools to create and build our products.

Experience in handling composite materials, using CNC machines and software, reading blueprints and drawings and a general understanding of manufacturing prinicples and systems are all desirable qualifications.

Schedule: Full-Time Salary

Job Level: Mid-Level (3-7 years)

Travel: 0 - 25

Success Profile

What makes a successful Production Planner at General Atomics? Check out the top traits we’re looking for and see if you have the right mix.

- Detail Oriented

- Team Player

- Results Driven

- Organized

- Productive

- Problem Solver

Job Summary General Atomics Aeronautical Systems, Inc. (GA-ASI), an affiliate of General Atomics, is a world leader in proven, reliable remotely piloted aircraft and tactical reconnaissance radars, as well as advanced high-resolution surveillance systems.

Under general supervision, this position is responsible for planning, preparing, issuing and controlling production schedules and coordinates with material requirements to ensure a controlled flow of approved materials timed to meet production requirements. Advises management of the status of work in progress, material availability, and potential production problems to ensure that personnel, equipment, materials and services are provided as needed.

DUTIES AND RESPONSIBILITES:

- Releases purchase requisitions to Procurement team to support manufacturing material requirements.

- Contributes to efficient operation of organization by inputting to or preparing short and long-range plans and schedules reports and providing progress follow-up and adjustment information.; develops planning activities that support schedule development; schedules, monitors performance, analyzes and reports on activities to ensure flow of material.

- Develops manufacturing work orders in accordance with Material Requirement Planning (MRP) planned order requirements; guides manufacturing on action(s) to be taken.

- Investigates and resolves manufacturing related issues; performs product assessments for part or product designs; provides input for manufacturing processes and manufacturing technologies to meet cost and schedules.

- Processes work orders and material transactions for non-conformance material dispositions.

- Interprets engineering change orders (ECO), implements dispositions affecting stock, work in progress, and NEXT assembly.

- Develops standard and non-standard reports; identifies issues, exceptions and variances and develops solutions to moderately complex issues; reviews processes and procedures to support business and regulatory agency requirements.

- Represents group with interdepartmental activity with quality, manufacturing, purchasing, engineering and inventory control.

- Alerts operating or project management to deviation from established norms; develops and recommends solutions to a variety of problems of moderate scope and complexity.

- Responsible for observing all laws, regulations and other applicable obligations wherever and whenever business is conducted on behalf of the Company.

- Expected to work in a safe manner in accordance with established operating procedures and practices.

- Additional Functions:

- May perform physical movement of hardware as a result of processing NCR and ECO dispositions.

- Other duties as assigned or required.

Job Qualifications:

- Typically requires a Bachelors degree in Business Administration with an emphasis in Planning, Engineering, Production Control or a related discipline and three or more years progressive experience in planning, scheduling, budgeting and performance measurement. May substitute equivalent experience in lieu of education.

- Must have a general understanding of manufacturing planning principles, theories and concepts as well as ability to understand accounting and manufacturing systems in a research or production environment and to learn and apply basic planning tools and techniques; and knowledge of concepts and principles of planning to develop solutions to a variety of problems.

- Must be customer focused and possess:

- The ability to identify issues and interpret data including engineering drawings.

- Organization skills to maintain flow of work within the unit.

- Good interpersonal, verbal and written communication skills to interface with internal employees and to accurately document, report and present.

- Ability to maintain strict confidentiality of sensitive information.

- Knowledge of computer operations and applications and word processing and spreadsheets.

- Ability to work both independently and in a team environment is essential as is the ability to work extended hours as required.

Salary:$56,820 - $96,015

Benefits

-

Competitive Pay

-

Paid Time Off

-

Healthcare

-

Multiple product lines means a variety of work

-

Pension, 401(k)/Retirement Plans

-

Travel

“The people I work with and the great opportunities to grow are the reasons I look forward to coming to work every day.”– Ralph, Technician

“I enjoy working with good people and knowing I am helping our great military.”– Joe, Fabricator

“I chose General Atomics because I wanted to work in a challenging work environment.”– Tony, Composite Technician

“I'm excited to come to work because of the new projects and challenges.”– James, Quality Composite Inspector

News

-

Featured Jobs

- Senior Flight Software Engineer Albuquerque, New Mexico

- Information System Security Officer - ISSO Poway, California

- Flight Test Engineer Palmdale, California

- Senior System Integration Engineer San Diego, California

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Senior Flight Software Engineer Albuquerque, New Mexico

- Information System Security Officer - ISSO Poway, California

- Flight Test Engineer Palmdale, California

- Senior System Integration Engineer San Diego, California

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Senior Flight Software Engineer Albuquerque, New Mexico

- Information System Security Officer - ISSO Poway, California

- Flight Test Engineer Palmdale, California

- Senior System Integration Engineer San Diego, California

You have not recently viewed any jobs.

You have no saved jobs.