Aircraft Technician - Lead (Second Shift)

Poway, California

Overview

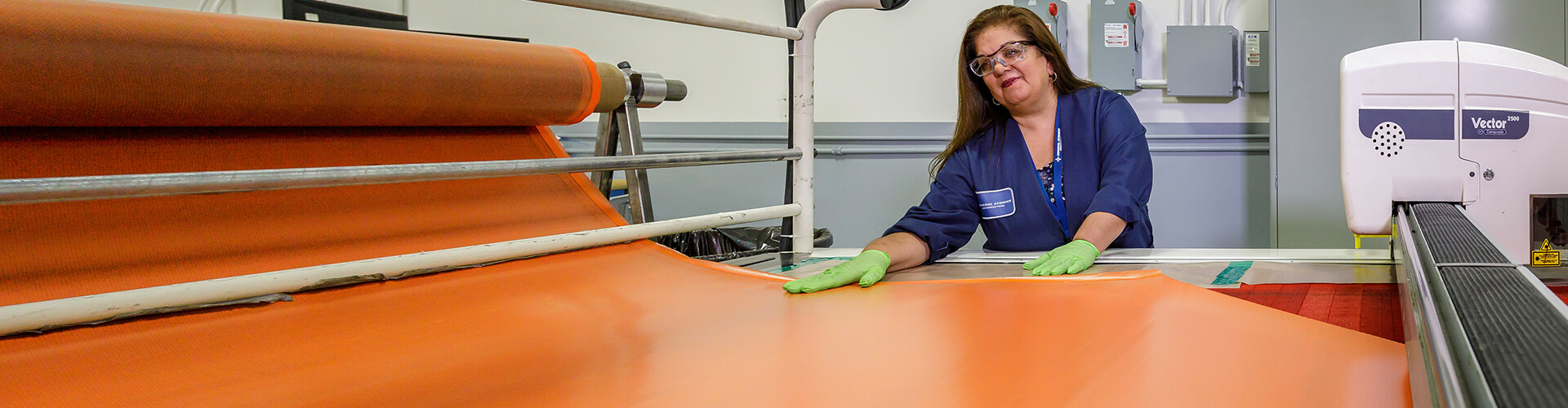

Assemblers, Machinists, Material and Production Control, Composite Technicians, Coordinators, Planners and Stock Clerks. These are just a few of the Manufacturing positions we offer at General Atomics. As a Manufacturing team member, you will use high-tech machines, systems, equipment and tools to create and build our products.

Experience in handling composite materials, using CNC machines and software, reading blueprints and drawings and a general understanding of manufacturing prinicples and systems are all desirable qualifications.

Schedule: Full-Time Hourly

Job Level: Mid-Level (3-7 years)

Travel: 0 - 25

Success Profile

What makes a successful Aircraft Technician - Lead (Second Shift) at General Atomics? Check out the top traits we’re looking for and see if you have the right mix.

- Detail Oriented

- Team Player

- Results Driven

- Organized

- Productive

- Problem Solver

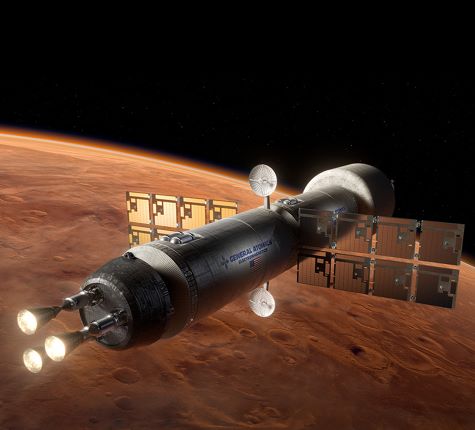

Job Summary General Atomics Aeronautical Systems, Inc. (GA-ASI), an affiliate of General Atomics, is a world leader in proven, reliable remotely piloted aircraft and tactical reconnaissance radars, as well as advanced high-resolution surveillance systems.

Performs and/or assists in modification, fabrication, assembly, operations, installation, repair and maintenance of Unmanned Aerial Vehicles (UAV) aircraft.

JOB DUTIES & RESPONSIBILITIES

- Lead and oversee the integration of various aircraft systems and components.

- Perform complex assignments related to the integration process in accordance with work instructions.

- Utilize extensive hands-on aircraft experience in the removal and replacement of components during integration activities.

- Troubleshoot and resolve complex integration issues, ensuring seamless system functionality.

- Interpret and work from blueprints, drawings, and engineering specifications to facilitate accurate integration.

- Ensure all integration activities adhere to FOD (Foreign Object Debris) and Tool Control operating procedures.

- Operate common hand tools and lifting equipment safely and effectively during integration tasks.

- Maintain accurate records and documentation related to integration processes.

- Collaborate effectively with engineering, production, and quality assurance teams.

- Provide guidance and mentorship to other technicians on the integration team.

- Utilize knowledge of computer operations and relevant software applications for documentation and communication.

- Observe all laws, regulations, and other applicable obligations wherever and whenever business is conducted on behalf of the Company.

- Work in a safe manner in accordance with established operating practices and procedures.

- Work extended hours when required to meet project timelines.

- Perform other duties as assigned or requested.

- Proven leadership and mentoring abilities.

- Extensive hands-on experience with aircraft systems and component integration.

- Strong understanding of aircraft blueprints, drawings, and engineering specifications.

- Proficient in the use of common hand tools and operation of lifting equipment.

- Excellent problem-solving and troubleshooting skills related to system integration.

- Strong attention to detail and commitment to quality.

- Familiarity with FOD and Tool Control procedures.

- Effective communication and interpersonal skills.

- Ability to work independently and as part of a team.

- Basic computer skills and proficiency in relevant software applications.

Job Qualifications:

- Typically requires associate's degree or equivalent with five or more years of experience. May substitute equivalent experience in lieu of education.

- Must have at least 4 years of hands-on aircraft experience in the removal and replacement of components.

- Must be familiar with FOD and Tool Control operating procedures.

- Must have the capability to perform complex assignments in accordance with work instructions.

- Knowledge of computer operations and applications pertinent to department functions is required.

- Must be able to work with common hand tools and operate lifting equipment

- Ability to obtain and maintain a Department of Defense (DoD) Secret level security clearance is required. Active Secret level clearance is desired.

Salary:$60,670 - $90,198

Benefits

-

Competitive Pay

-

Paid Time Off

-

Healthcare

-

Multiple product lines means a variety of work

-

Pension, 401(k)/Retirement Plans

-

Travel

“The people I work with and the great opportunities to grow are the reasons I look forward to coming to work every day.”– Ralph, Technician

“I enjoy working with good people and knowing I am helping our great military.”– Joe, Fabricator

“I chose General Atomics because I wanted to work in a challenging work environment.”– Tony, Composite Technician

“I'm excited to come to work because of the new projects and challenges.”– James, Quality Composite Inspector

News

-

Featured Jobs

- Legal Assistant San Diego, California

- Senior Subcontract Administrator Poway, California

- Project Systems Engineer Poway, California

- Electrical Engineer, Hardware Description Language (MODEM), and Embedded Software San Diego, California

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Legal Assistant San Diego, California

- Senior Subcontract Administrator Poway, California

- Project Systems Engineer Poway, California

- Electrical Engineer, Hardware Description Language (MODEM), and Embedded Software San Diego, California

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Legal Assistant San Diego, California

- Senior Subcontract Administrator Poway, California

- Project Systems Engineer Poway, California

- Electrical Engineer, Hardware Description Language (MODEM), and Embedded Software San Diego, California

You have not recently viewed any jobs.

You have no saved jobs.