Aircraft Engine Shop Production Supervisor

Palmdale, California

Overview

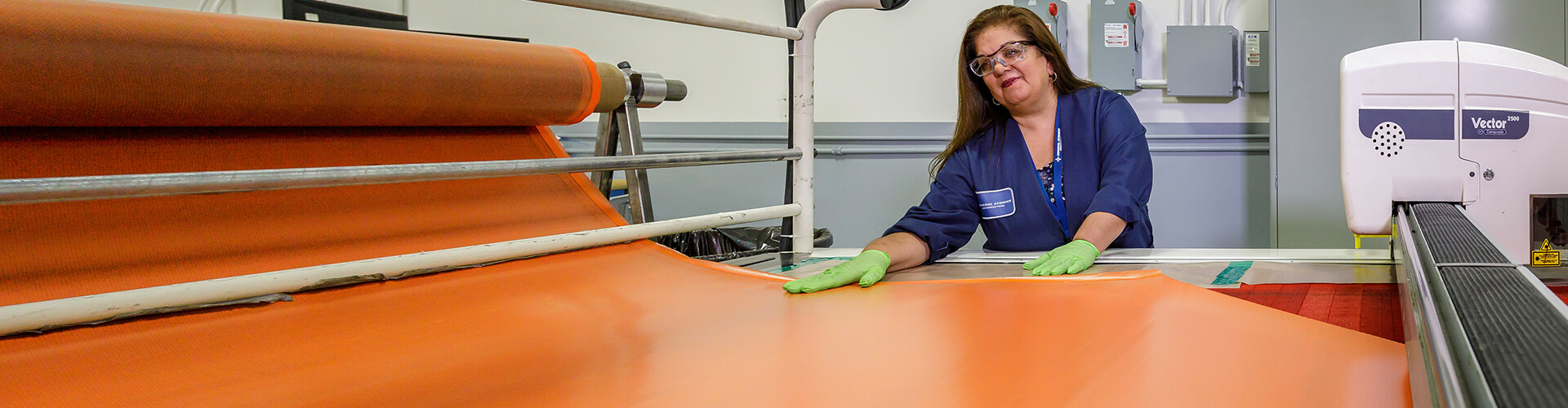

Assemblers, Machinists, Material and Production Control, Composite Technicians, Coordinators, Planners and Stock Clerks. These are just a few of the Manufacturing positions we offer at General Atomics. As a Manufacturing team member, you will use high-tech machines, systems, equipment and tools to create and build our products.

Experience in handling composite materials, using CNC machines and software, reading blueprints and drawings and a general understanding of manufacturing prinicples and systems are all desirable qualifications.

Schedule: Full-Time Salary

Job Level: Supervisory

Travel: 0 - 25

Success Profile

What makes a successful Aircraft Engine Shop Production Supervisor at General Atomics? Check out the top traits we’re looking for and see if you have the right mix.

- Detail Oriented

- Team Player

- Results Driven

- Organized

- Productive

- Problem Solver

Job Summary General Atomics Aeronautical Systems, Inc. (GA-ASI), an affiliate of General Atomics, is a world leader in proven, reliable remotely piloted aircraft and tactical reconnaissance radars, as well as advanced high-resolution surveillance systems.

The Engine Shop Supervisor position develops, schedules, and implements work activities for the propulsion groups manufacturing, field return, special projects, pre-production, and repair areas. Coordinates day to day activities across multiple sites including personnel supervision, work assignments, and coordination of the workflow through the sites. Requires complete familiarity with and understanding of the general aspects and technical phases of the job.

DUTIES AND RESPONSIBILITIES:

- Supervises technicians through all phases of engineering shops and production areas as needed in accordance with established schedules. Offers guidance and coaching to employees.

- Schedules and coordinates work assignments. Ensures accurate time charging.

- Examines shop equipment for defects to prevent injuries and equipment malfunctions, reports needed repairs.

- Assists engineering staff to resolve design and documentation issues. Interfaces with planning personnel in the generation of process flows, as well as with quality assurance personnel.

- Analyzes work orders and blueprints to determine information such as material to be used, type of operations, and sequence of operations required. Monitors usage and supply of all production materials and tooling; reorders when necessary. Interfaces with production control to help prevent material and equipment shortages.

- Formulates and recommends plans, policies, procedures and schedules for the section. Seeks methods to improve product quality, repeatability and efficiency.

- Evaluates work standards and performance levels ensuring uniformity, effectiveness and appropriate staffing levels. Inspects work in progress and finished products.

- Recommends measures to improve production methods, equipment performance and quality of product. Suggests changes in working conditions and use of equipment to increase efficiency of shop.

- Interviews prospective employees. Responsible for training, qualification and certification when applicable. Provides mentoring to employees in developmental stages.

- Documentation review including but not limited to, engineering drawings, bill of materials, Service Bulletins, Field Manuals, Test Plans.

- Recommends measures to improve production methods, equipment performance and quality of product. Suggests changes in working conditions and use of equipment to increase efficiency of shop.

- Keeps management informed of product performance, quality status, risks, and customer concerns. Passes information up and down the management chain efficiently and effectively.

- Thrives in a fast-paced work environment with constant change of tasks and expected completion dates.

- Responsible for observing all laws, regulations and other applicable obligations wherever and whenever business is conducted on behalf of the Company. Expected to work and lead the workplace in a safe manner in accordance with established operating procedures and practices.

- Additional Functions:

- May interface with outside vendors and sales representatives to stay current on new products and services.

- Other duties as assigned or required.

Job Qualifications:

- Typically requires a bachelor's degree and nine or more years of progressive professional experience in a related technical field with at least three of those years in a supervisory capacity. May substitute equivalent experience in lieu of education.

- Must have a thorough technical understanding of production and assembly concepts and practices, with the ability to organize, schedule, and coordinate workloads and staff to meet established milestones.

- Must be customer focused and possess:

- The ability to identify issues, analyze and interpret data and develop innovative solutions to a variety of moderately complex matters of diverse scope and nature.

- Strong analytical, verbal, and written communication skills to accurately document, report, and present findings to a variety of audiences.

- Strong interpersonal skills to influence and guide all levels of employees and external representatives.

- The ability to maintain the confidentiality of sensitive information.

- The ability to represent the company on external projects.

- Strong computer skills.

- Must have flexibility to work any shift, if necessary. and travel as required.

- Ability to obtain and maintain DOD security clearance may be required.

- FAA PowerPlant License.

- Experience in servicing reciprocating and gas-turbine engines.

- General understanding of electrical circuits.

Salary:$73,700 - $128,780

Benefits

-

Competitive Pay

-

Paid Time Off

-

Healthcare

-

Multiple product lines means a variety of work

-

Pension, 401(k)/Retirement Plans

-

Travel

“The people I work with and the great opportunities to grow are the reasons I look forward to coming to work every day.”– Ralph, Technician

“I enjoy working with good people and knowing I am helping our great military.”– Joe, Fabricator

“I chose General Atomics because I wanted to work in a challenging work environment.”– Tony, Composite Technician

“I'm excited to come to work because of the new projects and challenges.”– James, Quality Composite Inspector

News

-

Featured Jobs

- Senior Flight Software Engineer Albuquerque, New Mexico

- Information System Security Officer - ISSO Poway, California

- Flight Test Engineer Palmdale, California

- Senior System Integration Engineer San Diego, California

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Senior Flight Software Engineer Albuquerque, New Mexico

- Information System Security Officer - ISSO Poway, California

- Flight Test Engineer Palmdale, California

- Senior System Integration Engineer San Diego, California

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Senior Flight Software Engineer Albuquerque, New Mexico

- Information System Security Officer - ISSO Poway, California

- Flight Test Engineer Palmdale, California

- Senior System Integration Engineer San Diego, California

You have not recently viewed any jobs.

You have no saved jobs.