Production Assembly Supervisor

San Diego, CaliforniaOverview

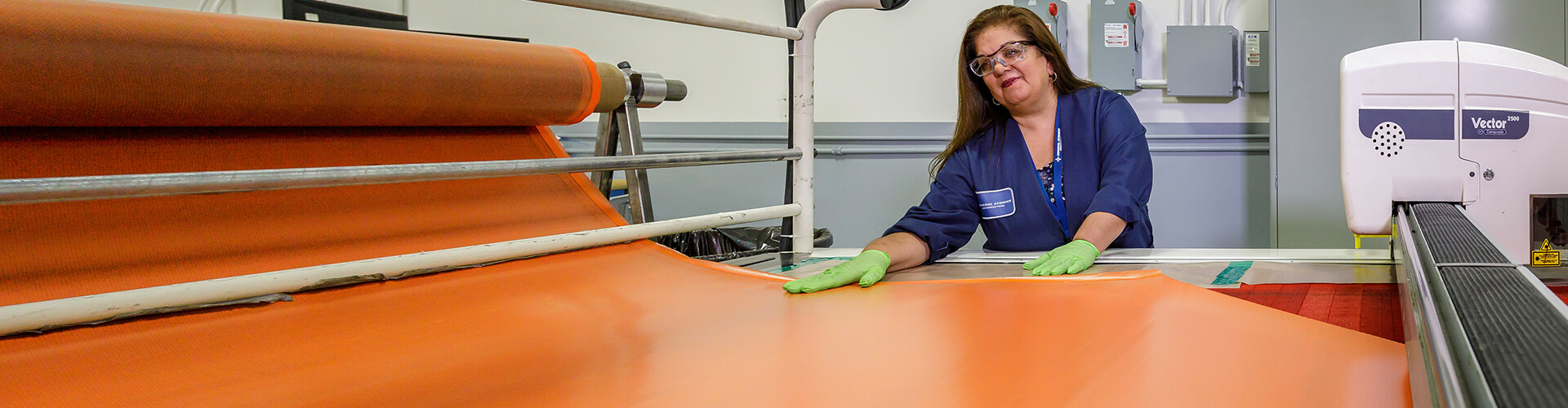

Assemblers, Machinists, Material and Production Control, Composite Technicians, Coordinators, Planners and Stock Clerks. These are just a few of the Manufacturing positions we offer at General Atomics. As a Manufacturing team member, you will use high-tech machines, systems, equipment and tools to create and build our products.

Experience in handling composite materials, using CNC machines and software, reading blueprints and drawings and a general understanding of manufacturing prinicples and systems are all desirable qualifications.

Schedule: Full-Time Salary

Job Level: Supervisory

Travel: 0 - 25

Success Profile

What makes a successful Production Assembly Supervisor at General Atomics? Check out the top traits we’re looking for and see if you have the right mix.

- Detail Oriented

- Team Player

- Results Driven

- Organized

- Productive

- Problem Solver

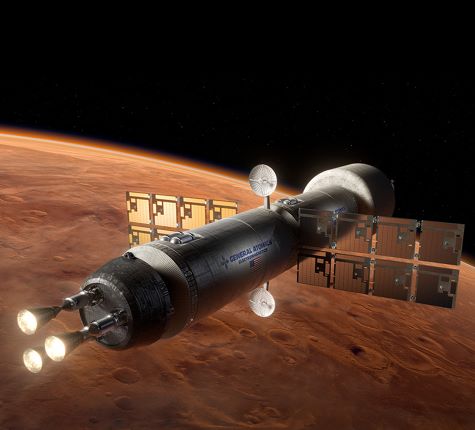

Job Summary General Atomics (GA), and its affiliated companies, is one of the world’s leading resources for high-technology systems development ranging from the nuclear fuel cycle to remotely piloted aircraft, airborne sensors, and advanced electric, electronic, wireless and laser technologies.

This position is responsible for managing day to day production and developmental programs. Develops and manages activities for the manufacturing and assembly area. Establishes operating policies and procedures and interprets, executes and recommends modifications to organizational policies. Coordinates activities of the production process, including supervising personnel, assigning work, and coordinating product flow through the production and final assembly phases.

Roles And Responsibilities

- Supervises production and Manufacturing Engineering staff in various locations through all phases of production. Offers guidance and coaching to manufacturing engineering personnel.

- Oversees the design and building of tooling needed for the production process.

- Represents the production and manufacturing engineering group with planning, test, quality, production control and engineering staff. Represents the group with outside vendors and customers regarding projects, operations, scheduling and contractual requirements.

- Analyzes work orders and blueprints to determine information such as material to be used, type and sequence of operations required. Ensures and monitors adequate usage and supply of all production materials and tooling.

- Interprets, executes and recommends plans, policies, procedures and schedules.

- Schedules and coordinates work assignments. Ensures accurate time charging.

- Participates in the development of over-all objectives and long term goals of the group.

- Implements measures to improve production methods, equipment performance and quality of product. Develops and oversees changes in working conditions and use of equipment to increase efficiency of the departments.

- Oversees configuration changes in the product and supports field upgrades and operations.

- Manages and participates in the planning, attraction, selection, retention, and development of human resources. Assigns, directs and reviews the work of employees.

- Responsible for observing all laws, regulations and other applicable obligations wherever and whenever business is conducted on behalf of the Company. Expected to work and lead the workplace in a safe manner in accordance with established operating procedures and practices.

- Other duties as assigned or required.

We recognize and appreciate the value and contributions of individuals with diverse backgrounds and experiences and welcome all qualified individuals to apply.

Job Qualifications:

- Typically requires a bachelor's degree and eleven or more years of progressive professional experience in a production-related environment emphasizing complex manufacturing and assembly techniques. May substitute equivalent experience in lieu of education.

- Must demonstrate extensive technical knowledge of production and assembly concepts and practices, and the ability to organize, schedule, and coordinate workloads and staff to meet established milestones

- Must have extensive knowledge in CNC machining and the machining of complex parts for aerospace and department of defense work.

- Must be able to coordinate and aid in process creation with machine shop team.

- Must be customer focused and possess:

- The ability to identify issues, analyze and interpret data and develop innovative solutions to a variety of unusually complex matters of diverse scope

- Excellent analytical, verbal and written communication skills to accurately document, report, and present findings to a variety of audiences including senior management and external parties

- Excellent interpersonal skills to influence and guide all levels of employees

- The ability to maintain the confidentiality of sensitive information

- The ability to initiate, plan, and manage multiple projects or programs, budgets and schedules

- The ability to manage multiple shifts

- The ability to represent the company on external projects

- Excellent computer skills.

- The ability to work extended hours is essential as is the ability to travel as required.

Salary:$89,180 - $155,825

Benefits

-

Competitive Pay

-

Paid Time Off

-

Healthcare

-

Multiple product lines means a variety of work

-

Pension, 401(k)/Retirement Plans

-

Travel

“The people I work with and the great opportunities to grow are the reasons I look forward to coming to work every day.”– Ralph, Technician

“I enjoy working with good people and knowing I am helping our great military.”– Joe, Fabricator

“I chose General Atomics because I wanted to work in a challenging work environment.”– Tony, Composite Technician

“I'm excited to come to work because of the new projects and challenges.”– James, Quality Composite Inspector

News

-

Featured Jobs

- Legal Assistant San Diego, California

- Electrical Engineer, MODEM Architect San Diego, California

- Project Systems Engineer Poway, California

- Quality Engineer Tupelo, Mississippi

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Legal Assistant San Diego, California

- Electrical Engineer, MODEM Architect San Diego, California

- Project Systems Engineer Poway, California

- Quality Engineer Tupelo, Mississippi

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Legal Assistant San Diego, California

- Electrical Engineer, MODEM Architect San Diego, California

- Project Systems Engineer Poway, California

- Quality Engineer Tupelo, Mississippi

You have not recently viewed any jobs.

You have no saved jobs.