Production and Engineering Liaison

Poway, CaliforniaOverview

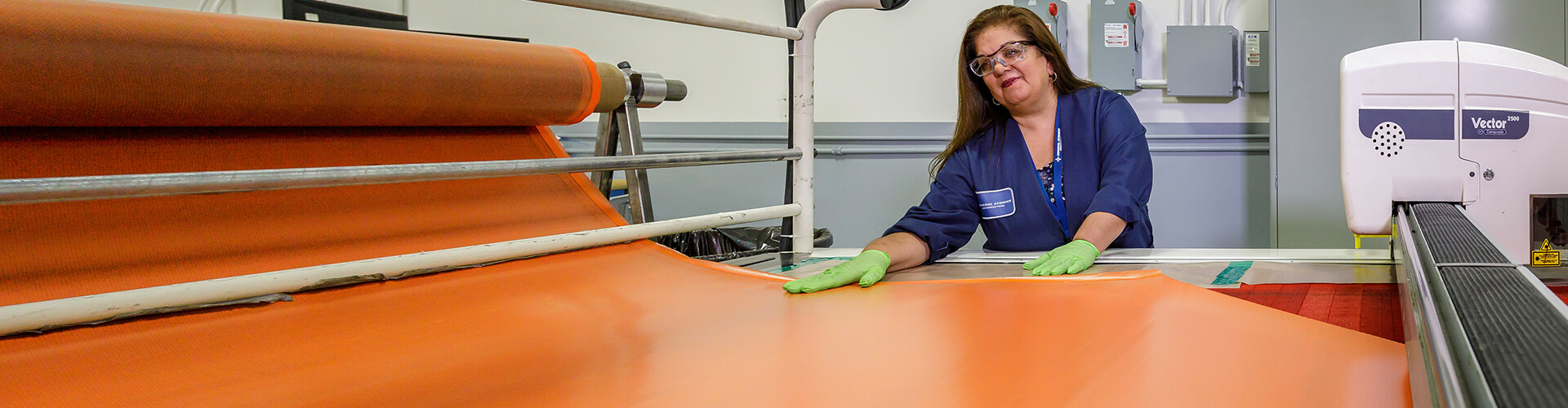

Assemblers, Machinists, Material and Production Control, Composite Technicians, Coordinators, Planners and Stock Clerks. These are just a few of the Manufacturing positions we offer at General Atomics. As a Manufacturing team member, you will use high-tech machines, systems, equipment and tools to create and build our products.

Experience in handling composite materials, using CNC machines and software, reading blueprints and drawings and a general understanding of manufacturing prinicples and systems are all desirable qualifications.

Schedule: Full-Time Salary

Job Level: Mid-Level (3-7 years)

Travel: 0 - 25

Success Profile

What makes a successful Production and Engineering Liaison at General Atomics? Check out the top traits we’re looking for and see if you have the right mix.

- Detail Oriented

- Team Player

- Results Driven

- Organized

- Productive

- Problem Solver

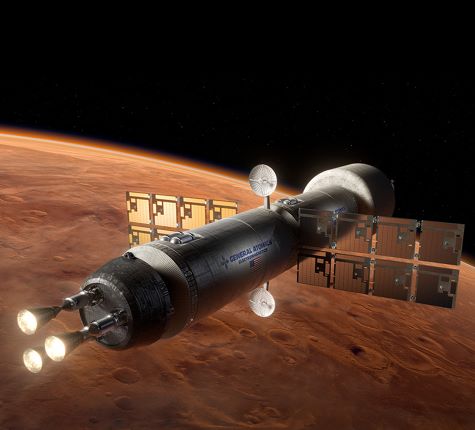

Job Summary General Atomics Aeronautical Systems, Inc. (GA-ASI), an affiliate of General Atomics, is a world leader in proven, reliable remotely piloted aircraft and tactical reconnaissance radars, as well as advanced high-resolution surveillance systems.

Under general direction, this position is responsible for developing and controlling manufacturing processes and evaluating and resolving production issues related to manufacturing, design, quality and material engineering. Analyzes, investigates and provides solutions to a variety of technical problems of moderate scope and complexity.

DUTIES AND RESPONSIBILITIES:

- Identify the requirements and specific operation steps for production of parts, assemblies and end items referencing engineering drawings, bills of material (BOM) and other applicable documentation.

- Develop work order routings for production master plans, rework orders, and similar including operation structure in the proper sequence, assignment of the appropriate work center, operation qualification requirements / pre-requisites, operation instruction text, required buyoffs / sign-offs, operation setup and run times, et al.

- Edit work order routings as required, such as in association with a non-conformance disposition, engineering change, process changes, etc in the company’s ERP/MES systems.

- Follows up with production throughout the build of new product to ensure the routing is adequate, evaluate feedback from a process perspective and make any adjustments accordingly.

- Writes work instructions in a manner that is easily understood by production personnel and still reflects the necessary engineering, quality and other applicable requirements and pertinent details.

- Monitor release of drawing redlines and engineering changes, update the affected work orders in a timely manner and keep records as necessary to ensure that all changes have been incorporated.

- Create, update and maintain work instruction documentation as required, obtaining necessary approvals and completing required process change documents.

- Assist with Manufacturing Bill of Material (MBOM) and any manufacturing synthetic part numbers required.

- Review existing often complex work order routings, configuration logs, MBOMs and related information for accuracy and completeness, identifying and correcting errors and making updates as required.

- Works diligently, maintaining close attention to details, ensuring work is complete, accurate, conforming to requirements and consistent with business process specifications.

- Develop and maintain routing templates for common and other key scenarios, and leverage those templates when practical for consistency, standardization, and best practices.

- Work centers

- Operation time standards / Time estimation

- Provide recommendations for potential manufacturing improvements.

- Maintaining strong communication and organizational skills to coordinate with multiple stakeholders as required.

- Additional Functions Other duties as assigned or required.

Job Qualifications:

- Typically requires a Bachelor's degree and five or more years of progressive professional experience in a technical capacity in production operations. May substitute equivalent experience in lieu of education.

- Must have complete knowledge of production and engineering support principles, theories and concepts; a complete understanding of practices, techniques, and standards; strong working knowledge and experience of Lean Manufacturing principles; and knowledge of tool design and concepts.

- Must be customer focused and possess:

- Ability to participate in the development of new concepts and communicate and apply them accurately throughout an evolving environment.

- Organization skills to coordinate work phases.

- Ability to determine the appropriate approach or project level and provide solutions to a variety of moderately complex technical problems.

- Good communication, documentation, presentation and interpersonal skills to effectively interact with all levels of employees and management.

- Ability to maintain the confidentiality of sensitive information.

- Strong computer skills.

- Ability to work independently or in a team environment is essential as is the ability to work extended hours and travel as required.

- Ability to obtain and maintain DoD Security Clearance is required.

Salary:$73,700 - $128,780

Benefits

-

Competitive Pay

-

Paid Time Off

-

Healthcare

-

Multiple product lines means a variety of work

-

Pension, 401(k)/Retirement Plans

-

Travel

“The people I work with and the great opportunities to grow are the reasons I look forward to coming to work every day.”– Ralph, Technician

“I enjoy working with good people and knowing I am helping our great military.”– Joe, Fabricator

“I chose General Atomics because I wanted to work in a challenging work environment.”– Tony, Composite Technician

“I'm excited to come to work because of the new projects and challenges.”– James, Quality Composite Inspector

News

-

Featured Jobs

- Legal Assistant San Diego, California

- International Contract Administrator San Diego, California

- Field Avionics Technician Emerado, North Dakota

- Electrical Engineer, Hardware and Circuit Board Design Lead San Diego, California

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Legal Assistant San Diego, California

- International Contract Administrator San Diego, California

- Field Avionics Technician Emerado, North Dakota

- Electrical Engineer, Hardware and Circuit Board Design Lead San Diego, California

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Legal Assistant San Diego, California

- International Contract Administrator San Diego, California

- Field Avionics Technician Emerado, North Dakota

- Electrical Engineer, Hardware and Circuit Board Design Lead San Diego, California

You have not recently viewed any jobs.

You have no saved jobs.