Production and Engineering Liaison

Poway, CaliforniaOverview

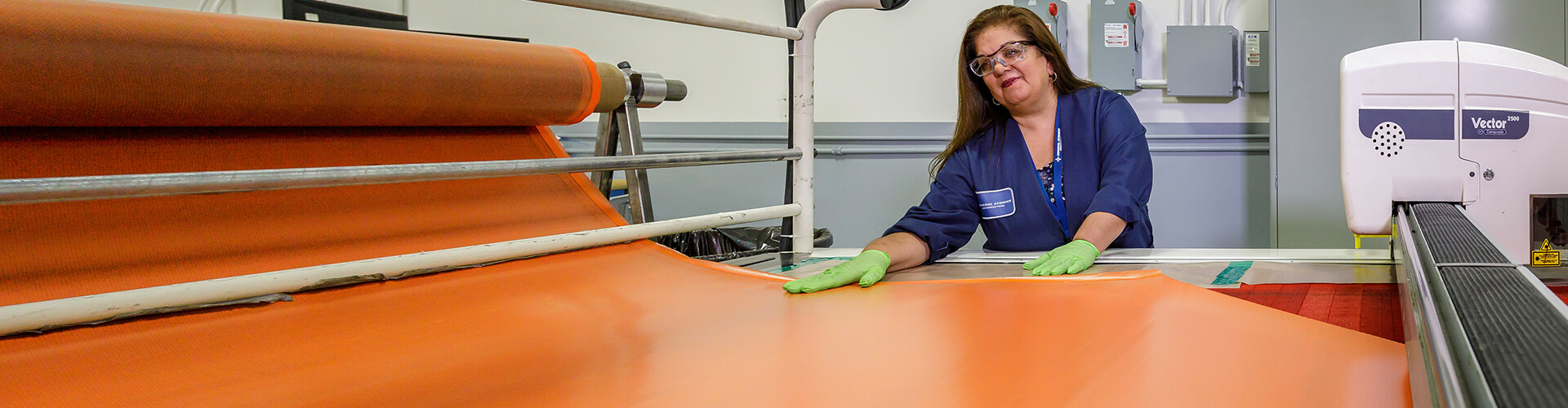

Assemblers, Machinists, Material and Production Control, Composite Technicians, Coordinators, Planners and Stock Clerks. These are just a few of the Manufacturing positions we offer at General Atomics. As a Manufacturing team member, you will use high-tech machines, systems, equipment and tools to create and build our products.

Experience in handling composite materials, using CNC machines and software, reading blueprints and drawings and a general understanding of manufacturing prinicples and systems are all desirable qualifications.

Schedule: Full-Time Salary

Job Level: Senior (8+ years)

Travel: 0 - 25

Success Profile

What makes a successful Production and Engineering Liaison at General Atomics? Check out the top traits we’re looking for and see if you have the right mix.

- Detail Oriented

- Team Player

- Results Driven

- Organized

- Productive

- Problem Solver

Job Summary General Atomics Aeronautical Systems, Inc. (GA-ASI), an affiliate of General Atomics, is a world leader in proven, reliable remotely piloted aircraft and tactical reconnaissance radars, as well as advanced high-resolution surveillance systems.

Under limited supervision, this position is responsible for developing and administering manufacturing processes and evaluating and resolving production issues related to manufacturing, design, quality and material engineering. Serves as an internal/external spokesperson to ensure company objectives are met. Exercises considerable latitude in determining objectives and approaches to assignments and develops solutions to complex problems.

DUTIES AND RESPONSIBILITIES:

- Provides leadership in the analysis, evaluation and resolution of engineering related production problems.

- Develops, implements and administers manufacturing processes, procedures and tooling.

- Analyzes defective, damaged or malfunctioning parts, assemblies, equipment and systems; analyzes and routes non-conforming reports; develops and implements corrective action.

- Identifies training needs and develops training plans and schedules.

- Represents the department as a primary contact with outside representatives; may represent department as member of change control board.

- Analyzes, investigates and recommends design and process changes; coordinates with engineering and manufacturing departments.

- Provides direction to support staff and may provide direction to less experienced professional staff.

- Responsible for observing all laws, regulations and other applicable obligations wherever and whenever business is conducted on behalf of the Company.

- Expected to maintain a productive and safe working environment in accordance with established operating procedures and practices.

- Assists in estimation of machined parts.

- Capable of technical project management. Includes expedite of parts through all phases of manufacture.

- Provides feedback to engineering for design for manufacture.

- Additional Functions Other duties as assigned or required.

We recognize and appreciate the value and contributions of individuals with diverse backgrounds and experiences and welcome all qualified individuals to apply.

Job Qualifications:

- Typically requires a Bachelor's degree and nine or more years of progressive professional experience in a technical capacity in production operations. May substitute equivalent experience in lieu of education.

- Must have a thorough knowledge of production and engineering administration principles, theories and concepts; a detailed understanding of practices, techniques, and standards; excellent working knowledge and experience of Lean Manufacturing principles; and knowledge of tool design and concepts.

- Must be customer focused and possess:

- Ability to participate in the development of new concepts and communicate and apply them accurately throughout an evolving environment.

- Organization skills to lead and coordinate work phases.

- Ability to determine the appropriate approach or project level and provide solutions to a variety of complex technical problems.

- Strong communication, documentation, presentation and interpersonal skills to effectively interact with all levels of employees, management and outside representatives.

- Ability to maintain the strict confidentiality of sensitive information.

- Excellent computer skills.

- Ability to work independently or lead in a team environment is essential as is the ability to work extended hours and travel as required.

Salary:$98,100 - $171,398

Benefits

-

Competitive Pay

-

Paid Time Off

-

Healthcare

-

Multiple product lines means a variety of work

-

Pension, 401(k)/Retirement Plans

-

Travel

“The people I work with and the great opportunities to grow are the reasons I look forward to coming to work every day.”– Ralph, Technician

“I enjoy working with good people and knowing I am helping our great military.”– Joe, Fabricator

“I chose General Atomics because I wanted to work in a challenging work environment.”– Tony, Composite Technician

“I'm excited to come to work because of the new projects and challenges.”– James, Quality Composite Inspector

News

-

Featured Jobs

- Legal Assistant San Diego, California

- Project Systems Engineer Poway, California

- Quality Engineer Tupelo, Mississippi

- Machinist Adelanto, California

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Legal Assistant San Diego, California

- Project Systems Engineer Poway, California

- Quality Engineer Tupelo, Mississippi

- Machinist Adelanto, California

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Legal Assistant San Diego, California

- Project Systems Engineer Poway, California

- Quality Engineer Tupelo, Mississippi

- Machinist Adelanto, California

You have not recently viewed any jobs.

You have no saved jobs.