Fabricator / Welder

Poway, CaliforniaOverview

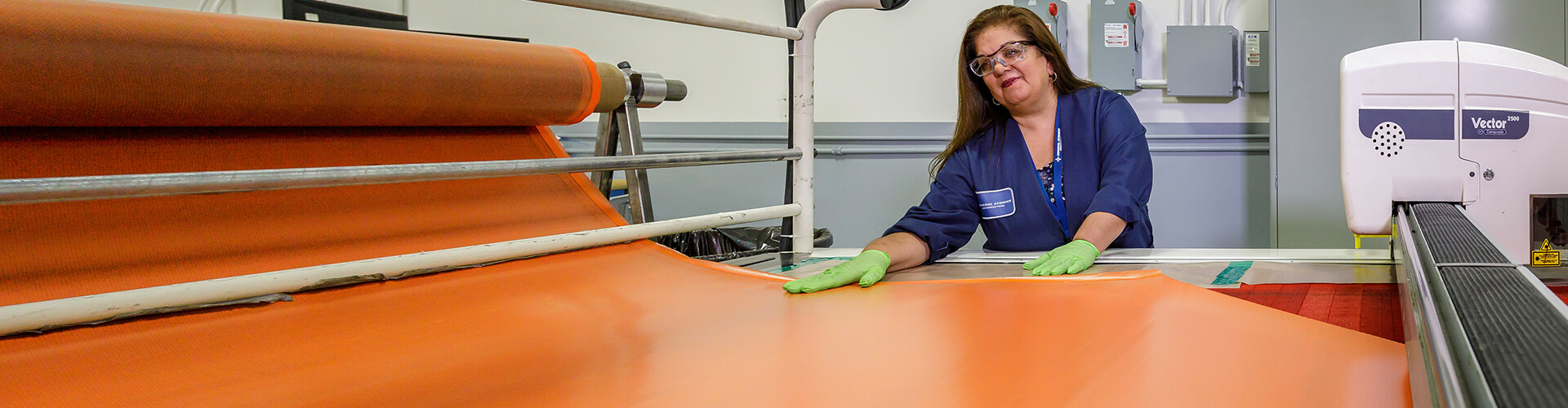

Assemblers, Machinists, Material and Production Control, Composite Technicians, Coordinators, Planners and Stock Clerks. These are just a few of the Manufacturing positions we offer at General Atomics. As a Manufacturing team member, you will use high-tech machines, systems, equipment and tools to create and build our products.

Experience in handling composite materials, using CNC machines and software, reading blueprints and drawings and a general understanding of manufacturing prinicples and systems are all desirable qualifications.

Schedule: Full-Time Hourly

Job Level: Mid-Level (3-7 years)

Travel: 0 - 25

Success Profile

What makes a successful Fabricator / Welder at General Atomics? Check out the top traits we’re looking for and see if you have the right mix.

- Detail Oriented

- Team Player

- Results Driven

- Organized

- Productive

- Problem Solver

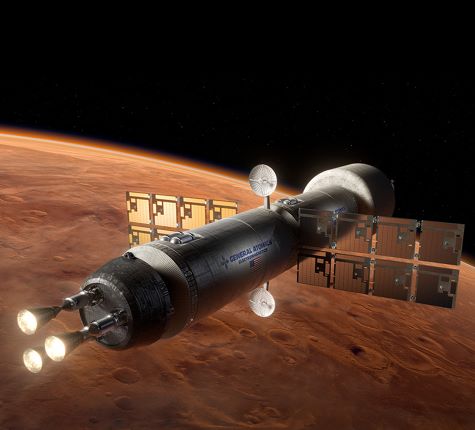

Job Summary General Atomics Aeronautical Systems, Inc. (GA-ASI), an affiliate of General Atomics, is a world leader in proven, reliable remotely piloted aircraft and tactical reconnaissance radars, as well as advanced high-resolution surveillance systems.

Under limited supervision, this position is responsible for designing and fabricating minor and major metal parts, tools and jigs through precision work on original and intricate layout, machining and assembly tasks. Performs tasks with limited instruction. Welds, lathes, heats, cuts, bends, solders, and drills from minimal descriptions. Sets up and operates precision tools.

DUTIES & RESPONSIBILITIES

- Designs and builds production tooling for fabricated parts.

- Performs prototype fabrication from visual descriptions or sketches. Prototypes engine parts.

- Forms sheet metal parts using a variety of machinist hand tools and precision measuring instruments.

- Runs manual mills, lathes, drill presses and grinding equipment to perform turning, facing, boring, chamfering, drilling, grooving, reaming, tapping and slotting.

- Sets up and operates a variety of engine lathes to perform quantity production machining to close tolerances.

- Performs plumbing operations using AN fittings with hard and flexible lines.

- Grinds own cutting tools, drills and bits.

- Designs and builds jigs and fixtures for producing weldments and dip brazing. Designs and builds press tooling for forming sheet metal parts.

- Performs welding, fitting and soldering on extremely thin ferrous and non-ferrous metals.

- Utilizes blue prints, sketches, drawings, verbal descriptions and sample parts to determine dimensions and tolerances of finished parts, the sequence of operations, and set up requirements.

- Responsible for observing all laws, regulations, and other applicable obligations wherever and whenever business is conducted on behalf of the Company.

- Expected to work in a safe manner in accordance with established operating procedures and practices.

- Additional Functions Other duties as assigned or required.

Job Qualifications:

- Typically requires an associate's degree, technical/trade school training or equivalent and three or more years experience in fabrication. Additional experience may be substituted for formal education.

- Knowledge of computer operations and applications required. Must be able to read and comprehend blueprints, engineering drawings, sketches and verbal and written communications to accomplish the job at hand.

- Must have the capability to perform complex assignments with little or no direction. Required to utilize independent judgment related to fabrication functions and activities. Able to weld to close tolerances.

- Must possess working knowledge of AN and MS fasteners, AN plumbing and aircraft riveting tools and procedures.

- Considerable knowledge of the position is required to ascertain problem situations and to recommend practical solutions to complex issue related to fabrication.

- Must be able to work independently or on a team providing solutions to a range of complex problems.

- Possesses good interpersonal skills, and verbal and written communication skills to interface with various levels of employees while performing fabrication functions.

- Ability to work in a team in a team environment is essential as is the ability to work extended hours as required.

Salary:$60,670 - $90,198

Benefits

-

Competitive Pay

-

Paid Time Off

-

Healthcare

-

Multiple product lines means a variety of work

-

Pension, 401(k)/Retirement Plans

-

Travel

“The people I work with and the great opportunities to grow are the reasons I look forward to coming to work every day.”– Ralph, Technician

“I enjoy working with good people and knowing I am helping our great military.”– Joe, Fabricator

“I chose General Atomics because I wanted to work in a challenging work environment.”– Tony, Composite Technician

“I'm excited to come to work because of the new projects and challenges.”– James, Quality Composite Inspector

News

-

Featured Jobs

- Legal Assistant San Diego, California

- International Contract Administrator San Diego, California

- Field Avionics Technician Emerado, North Dakota

- Electrical Engineer, Hardware and Circuit Board Design Lead San Diego, California

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Legal Assistant San Diego, California

- International Contract Administrator San Diego, California

- Field Avionics Technician Emerado, North Dakota

- Electrical Engineer, Hardware and Circuit Board Design Lead San Diego, California

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Legal Assistant San Diego, California

- International Contract Administrator San Diego, California

- Field Avionics Technician Emerado, North Dakota

- Electrical Engineer, Hardware and Circuit Board Design Lead San Diego, California

You have not recently viewed any jobs.

You have no saved jobs.