Composite Manufacturing Engineer

Poway, CaliforniaOverview

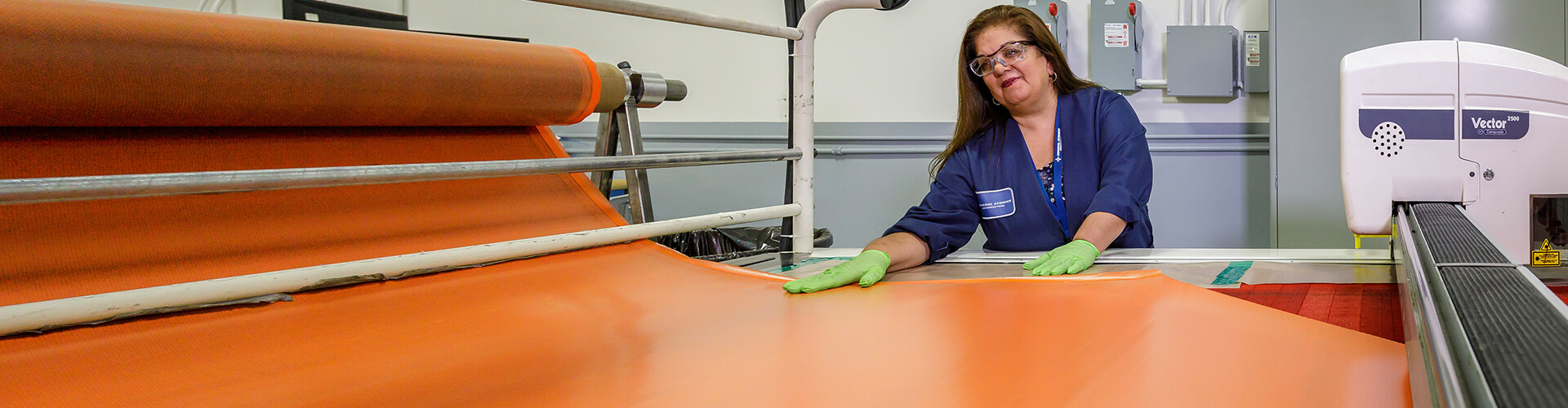

Assemblers, Machinists, Material and Production Control, Composite Technicians, Coordinators, Planners and Stock Clerks. These are just a few of the Manufacturing positions we offer at General Atomics. As a Manufacturing team member, you will use high-tech machines, systems, equipment and tools to create and build our products.

Experience in handling composite materials, using CNC machines and software, reading blueprints and drawings and a general understanding of manufacturing prinicples and systems are all desirable qualifications.

Schedule: Full-Time Salary

Job Level: Mid-Level (3-7 years)

Travel: 0 - 25

Success Profile

What makes a successful Composite Manufacturing Engineer at General Atomics? Check out the top traits we’re looking for and see if you have the right mix.

- Detail Oriented

- Team Player

- Results Driven

- Organized

- Productive

- Problem Solver

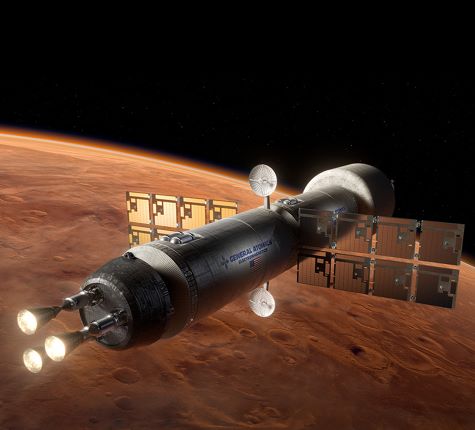

Job Summary General Atomics Aeronautical Systems, Inc. (GA-ASI), an affiliate of General Atomics, is a world leader in proven, reliable remotely piloted aircraft and tactical reconnaissance radars, as well as advanced high-resolution surveillance systems.

We have an exciting opportunity for an Experienced Composites Manufacturing Engineer in our GA-ASI/Aircraft Systems Group supporting 2nd shift Advanced Aerostructure Assembly.

Several of GA-ASI Composites Manufacturing Engineering roles/responsibilities are centered on projects/programs. Projects/programs include the support and oversight of current production to help mature manufacturing lines (materials, processes, and Continuous Improvement), as well as Design for Manufacturing (DFM) support for new products, including facility improvements/expansion and capital acquisition.

As an experienced Composite Manufacturing Engineer your role will be to lead and support - through rigorous quantitative analysis - multiple projects within GA-ASI’s product/platform line including but not limited to: Grey Eagle Extended Range (GE-ER), Certified Sky Guardian / Sea Guardian (MQ9B), Collaborative Combat Aircraft (CCA), and special projects. This includes leading/supporting top-tier teams of Manufacturing Engineers and technicians and developing manufacturing technology while ensuring aerospace standards and quality requirements are met. This position required depth and breadth of aerospace composite manufacturing, processing and materials knowledge. Project engineering and leadership experience are required. Must be able to multitask multiple and complex projects while staying organized in a fast-paced environment. Must be able to collaborate, negotiate, and work with internal and external groups to ensure ideas come to fruition

DUTIES AND RESPONSIBILITIES:

- Able to work independently, and with experienced engineers to devise new approaches to resolve unusual or highly complex manufacturing problems; through early, upfront design-for-manufacturing (DFM) principles to ensure producibility, inspect-ability, testability, maintainability and repairability.

- Responsible for a portion, or for all of the manufacturing value stream for a product line or process. Aspects include development, implementation, and continuous improvement to enhance Quality/ Yield, reduce Cost, and improve Productivity/Schedule.

- Troubleshoot conflicting design development vs. production requirements, promotes new methods / process equipment, and evaluates special material requirements.

- Assist technicians and other engineers in building prototypes and pilot builds. Document the build process with standardized work instructions, define and implement new manufacturing technologies.

- Document, analyze, and troubleshooting issues that arise and make technical presentations as required to communicate issues up and downstream.

- Provides input to design, technical staff, briefs management, and participates effectively in a team of moderately experienced professional staff.

- Assist in the development of manufacturing processes, procedures and tooling using technical experience and collaborative interaction with the team to improve quality, eliminate non-value-added steps and shorten lead times.

- Collaborate heavily with Design Engineering, Tooling Design, and Quality during prototype development, and first article manufacturing.

- Provide support for the disposition of non-conforming Product, identify root cause, and assist in the implementation of corrective/preventative actions.

- Review and approve engineering design and changes and ensure their manufacturability.

- Obtains and analyzes manufacturing and test data.

- Develops and maintains work instructions to guide technicians in the assembly of assigned products.

- Liaison work orders as required to reflect process changes, non-conformity dispositions and engineering changes.

- Responsible for observing all laws, regulations, and other applicable obligations wherever and whenever business is conducted on behalf of the Company.

- Expected to work in a safe manner in accordance with established operating procedures and practices. This is a 2nd shift position.

Job Qualifications:

- Typically requires a bachelor’s degree, master’s degree or PhD in engineering or a related technical discipline from an accredited institution and progressive engineering experience as follows; four or more years of experience with a bachelor’s degree, two or more years of experience with a master’s degree. May substitute equivalent engineering experience in lieu of education.

- Must have a thorough understanding of engineering concepts, principles, codes, and theory; experience demonstrating a broad application of those concepts; and expanding knowledge of principles, concepts, theory, and practices in related technical specialties.

- Must possess the ability to understand new concepts quickly; apply them accurately throughout an evolving environment; organize, schedule, and coordinate work phases; and determine the appropriate approach at the task level or, with assistance, at the project level to provide solutions to a range of complex problems.

- Must have strong communication, computer, documentation, presentation, and interpersonal skills, ability to work independently and as part of a team; able to perform complex tasks in one or more engineering areas; capable of representing the organization as a prime technical contact and lead a team of moderately experienced professional employees on single component projects.

- Previous work experience in Aerospace Manufacturing, primarily Composite Manufacturing and Mechanical Assembly and/or Tooling is preferred.

- Experience with Lean Manufacturing methodologies for waste reduction, e.g., 5S, Standard Work, TAKT, Pull System, 5S, Value Stream Mapping, cell design, and Manufacturing Flow, as well as GD&T is desirable.

- Ability to obtain and maintain a DoD secret clearance is required

- Must be customer focused and able to work on a self-initiated basis or in a team environment.

- Able to work extended hours as required.

Salary:$81,080 - $141,650

Benefits

-

Competitive Pay

-

Paid Time Off

-

Healthcare

-

Multiple product lines means a variety of work

-

Pension, 401(k)/Retirement Plans

-

Travel

“The people I work with and the great opportunities to grow are the reasons I look forward to coming to work every day.”– Ralph, Technician

“I enjoy working with good people and knowing I am helping our great military.”– Joe, Fabricator

“I chose General Atomics because I wanted to work in a challenging work environment.”– Tony, Composite Technician

“I'm excited to come to work because of the new projects and challenges.”– James, Quality Composite Inspector

News

-

Featured Jobs

- Legal Assistant San Diego, California

- International Contract Administrator San Diego, California

- Field Avionics Technician Emerado, North Dakota

- Electrical Engineer, Hardware and Circuit Board Design Lead San Diego, California

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Legal Assistant San Diego, California

- International Contract Administrator San Diego, California

- Field Avionics Technician Emerado, North Dakota

- Electrical Engineer, Hardware and Circuit Board Design Lead San Diego, California

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Legal Assistant San Diego, California

- International Contract Administrator San Diego, California

- Field Avionics Technician Emerado, North Dakota

- Electrical Engineer, Hardware and Circuit Board Design Lead San Diego, California

You have not recently viewed any jobs.

You have no saved jobs.