Additive Manufacturing Engineer

Poway, CaliforniaOverview

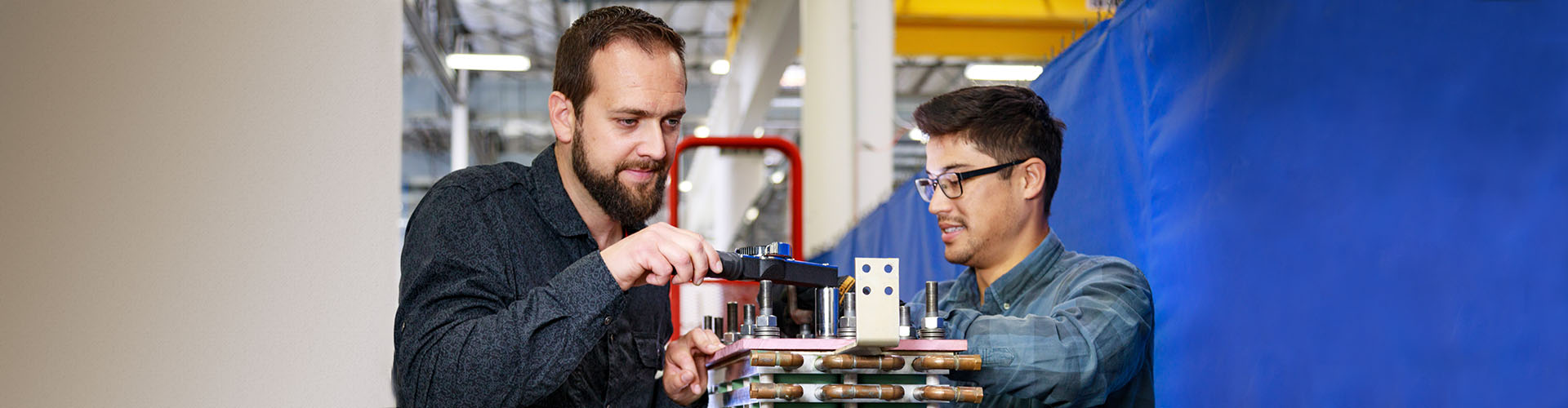

General Atomics pioneers technologies with the potential to change the world. Behind a talented global team of engineers, GA delivers safe, sustainable, and economical solutions to meet growing global demands. Our Engineers have an opportunity to work on first of a kind product lines within an incredible, dynamic environment.

Engineering positions typically require a bachelor’s degree, master’s degree or PhD in engineering or a related technical discipline from an accredited institution and progressive engineering experience. Candidates from mechanical, electrical, and aerospace engineering backgrounds must know the fundamentals of engineering system developments, requirements, testing, and integration before getting to the final stages of customer interface and project management.

Schedule: Full-Time Salary

Job Level: Mid-Level (3-7 years)

Travel: 0 - 25

Success Profile

What makes a successful Additive Manufacturing Engineer at General Atomics? Check out the top traits we’re looking for and see if you have the right mix.

- Analytical

- Collaborative

- Inventive

- Problem Solver

- Team Player

- Creative

Job Summary General Atomics Systems Integration, LLC (GA-SI), an affiliate of General Atomics, is a provider of military and commercial engineering services. GA-SI is a leading-edge expert in systems integration technologies, reliability improvements, and controls system design.

We have an exciting opportunity for a dynamic and self-driven Additive Manufacturing (AM) Engineer at General Atomics Systems Integration (GA-SI).

This position will occupy a strategic role in the growth of AM at GA-SI by advancing heat exchanger technology that can be applied across several aerospace platforms. This position will specifically work on a metal laser powder-bed fusion AM-related project and manufacturing operations to support flight-ready part manufacturing. This role will provide both AM technology and materials subject matter expertise towards new application development. This role will have a significant component of outward-facing interactions with various engineering, quality, and program stakeholder teams across General Atomics and its customers and subcontractors.

Although this position is part of the GA-SI Engineering Services division in Kaysville UT, this position will be co-located at the General Atomics Aeronautical Systems Inc. (GA-ASI) Poway, California location for approximately 1 year, and will be mentored by the GA-ASI AM center of excellence team. Following the first year, the position may be relocated to one of GA-SI’s other locations (likely Utah or Oklahoma).

DUTIES AND RESPONSIBILITIES:

- Become Subject Matter Expert (SME) on metal Laser Powder Bed Fusion (LPBF), and over time on other AM modalities. Technologies of interest to be supported by this role could include (but not limited to): Fused Deposition Modeling – FDM, Selective Laser Sintering – SLS, Laser Powder Bed Fusion – LPBF, Binder Jet (sand), LSAM/BAAM, Direct Energy Deposition – Wired (DED-W), DAPS™, SLA, DLP, MJF, ECAM, and other AM technologies.

- Working hand-in-hand with the metal LPBF manufacturing engineer in support of operations and new application development.

- Responsible for AM rapid development, qualification, and implementation.

- Support manufacturing production planning and coordination, execution and operations process development.

- Support and lead the planning and implementation of AM (incl. post-processing) equipment and associated processes and safety.

- Document manufacturing processes and assembly work instructions in conjunction with support staff.

- Revision of AM specification documentation with key Materials & Process stakeholders.

- Review engineering drawings, and provide expertise on metal LPBF during engineering review processes.

- Learn other AM modalities processes, materials and application space towards supporting new application development through design for AM, manufacturing process optimization and testing.

- Interface with engineering stakeholders such as design, materials, process and quality.

- Work closely with DfAM engineering on manufacturing/production operations, and assist with design engineering’s knowledge transfer and teaching efforts.

- Collaborate with Design Engineering during development, prototype and first article manufacturing.

We recognize and appreciate the value and contributions of individuals with diverse backgrounds and experiences and welcome all qualified individuals to apply.

Job Qualifications:

- Typically requires a bachelors degree, masters degree or PhD in engineering or a related technical discipline from an accredited institution and progressive engineering experience as follows; four or more years of experience with a bachelors degree or two or more years of experience with a masters degree. May substitute equivalent engineering experience in lieu of education.

- Background knowledge of conventional manufacturing processes (complementary to metal AM, such as CNC machining, casting, welding, metrology, assembly, bonding, etc.)

- Clearly and effectively communicate both verbally and in written form to both technical and non-technical audiences, especially regarding manufacturing processes, engineering issues and proposed changes, and quality issues and dispositions.

- Experience with Microsoft Office PowerPoint, Project, Excel and Visio.

- Experience with MRP systems is an advantage, (e.g. SAP or MTO/WDS.)

- Experience with PLM systems is an advantage (e.g. Teamcenter, Windchill, etc.)

- Must be able to work both independently and in a team environment.

- Must be self-driven, like to innovate, and a desire to learn.

- Ability to influence others, develop a plan and rally a team around it, lead small team.

- Able to work extended hours and travel as required.

- Must be able to obtain and maintain a DoD Security Clearance

- Experience in one or more of the following areas is highly beneficial, but not a requirement for the position. We expect there will be a learning curve and on-the-job opportunities to learn. The willingness and ability to learn new technologies is of primary importance.

- Direct experience with industrial-class production additive manufacturing technologies, processes and applications. Defense-related manufacturing environment is highly desired.

- Hands-on experience with Laser Powder Bed Fusion (LPBF) technologies metal AM as a designer, and as a user of the LPBF to manufacture industrial parts. Complementary hands-on experience with design and printing operations with other AM modalities (metal and non-metals) are also very valuable.

- Experience with the entire AM workflow from business considerations, design, pre-print considerations and planning, printing, post-processing and qualification process. Special considerations for metal LPBF technologies.

- Working knowledge of most key AM technologies, and their associated characteristics and applicability/use cases for defense/aviation/aerospace is highly desired.

- Experience in Design for Additive Manufacturing (DfAM).

- Experience dealing with AM suppliers (service bureaus, materials and hardware providers, software providers, etc.)

- Understanding of thermal dynamics and experience performing thermal analysis.

- Experience with heat exchanger design.

- Experience with Computational Fluid Dynamics (CFD).

Salary:$81,080 - $141,650

Benefits

-

Healthcare

-

Pension, 401(k)/Retirement Plans

-

Competitive Pay

-

Multiple product lines means a variety of work

-

Paid Time Off

“The company is growing, has a very good reputation and had open positions in my area of expertise (aircraft design/design methodology development).”– Peter, Senior Staff Engineer

“We don't ascribe to quotas; we do ascribe to securing the BEST talent to enrich our culture toward healthy diversification and active/viable community service. We are STEM advocates.”– Debra, CSSBB: Staff Engineer

“Every day is different, with different problems to solve and many programs to support. I am a problem solver and have always been motivated by the tough questions.”– Scott, Laser Scientist

“I work in the Components Engineering and Obsolescence Management Dept. Our efforts are saving General Atomics several millions of dollars by proactively leading and informing the company of all these decisions which significantly impact production, sustainment and new designs.”– John, Staff Engineer

News

-

Featured Jobs

- Legal Assistant San Diego, California

- Electrical Engineer, MODEM Architect San Diego, California

- Project Systems Engineer Poway, California

- Quality Engineer Tupelo, Mississippi

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Legal Assistant San Diego, California

- Electrical Engineer, MODEM Architect San Diego, California

- Project Systems Engineer Poway, California

- Quality Engineer Tupelo, Mississippi

You have not recently viewed any jobs.

You have no saved jobs.

-

Featured Jobs

- Legal Assistant San Diego, California

- Electrical Engineer, MODEM Architect San Diego, California

- Project Systems Engineer Poway, California

- Quality Engineer Tupelo, Mississippi

You have not recently viewed any jobs.

You have no saved jobs.